Case Study

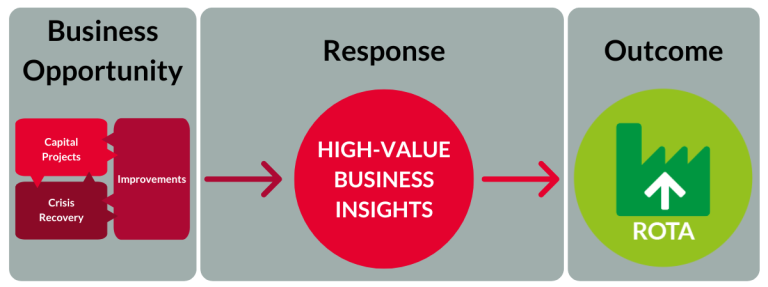

Opportunity

Bullant was asked to lead the design of the production equipment and services for a greenfield factory development. The factory would be required to produce product formats that were complex, had a wide size range and included a complex array of pack components .

Response

Bullant worked with client personnel to:

- Prepared a preliminary, optimised schedule showing the number of lines required.

- Created process maps for each of the 4 lines in the facility identifying expected running rates, efficiencies and v-curves.

- Completed the process design for the required services

- Designed the multiple vendor supply strategy reducing 3rd party supply margins

- Prepared the documentation required for the tender process.

Bullant then provided the client-side contract management required to deliver the project.

Outcome

A very complex project was kept on track despite an aggressive timeline.