Case Study

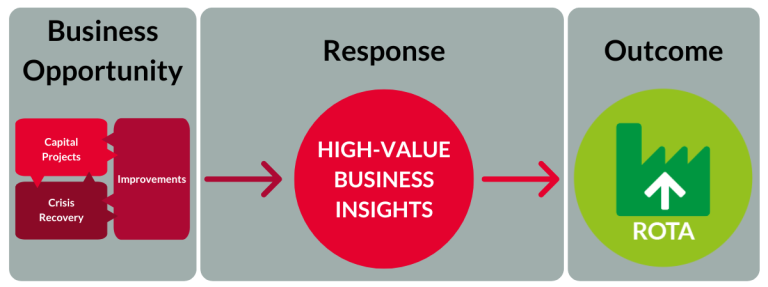

Opportunity

Bullant were asked to review the design of a multi-million dollar factory containing 2 complex processing lines planned for installation as part of a major capital project. The client wanted proof that the factory was actually designed to achieve the performance benefits stated in the project business case.

The client also wanted to confirm if a cheaper capital option, with less machinery, could still achieve the business case

Response

With the help of operations personnel, Bullant used Factory Analytics tools to create the following useful business insights:

- An optimised schedule showing the number and type of changeovers.

- A Process Map (Bullant Filters) showing the distribution of forecast demand, capacities and buffers on each line.

- An animated 3D Model showing the statistically relevant efficiency of each line for the different configurations required by each product family.

Outcome

The work confirmed the OEE capability of the 2 lines. It also highlighted design changes needed on the lines to deliver the performance goals in the project. This avoided considerable operating expense and production rate issues at startup.

We were also able to show that the cheaper capital option was actually better for delivering the business targets.